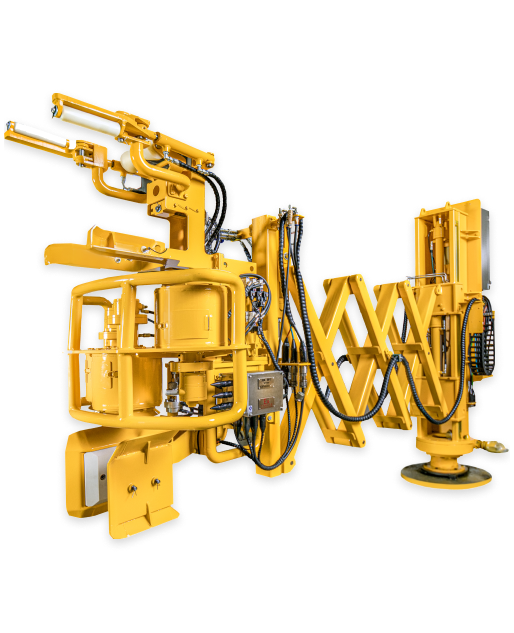

The Automatic Doper & Mud Bucket set blowout preverntion, thread cleaning and thread greasing function in one, is a drilling floor robot configured on the rig for handling drill pipe thread and prevent mud spatter, to completely liberate the drill floor staff, and finally realize the drill floor unmanned. The Automated Doper Kit and the Mud Bucket Kit is interchangeable and suits for pipe sizes from 3-1/2”to 6-5/8”. It can be connected with JJC machine vision module to realize one-button automatic operation.